How Do Injection Molding Machines Create Plastic Flowers?

Struggling with creating detailed plastic flowers1? Standard methods often fail to capture delicate details. But injection molding2 can perfectly craft intricate floral designs from simple plastic pellets.1

Injection molding machines create plastic flowers by melting plastic pellets3 and injecting the molten material into a custom-designed flower-shaped mold. The plastic cools and solidifies inside the mold, which is then opened to eject a perfectly formed, detailed flower part.2

<sup id=](https://aluledprofile.com/wp-content/uploads/2025/08/provide-an-illustration-for-the-following-text-how.jpg) 2" title="Injection Molded Plastic Flowers" />

2" title="Injection Molded Plastic Flowers" />

The process sounds straightforward, but creating a delicate flower is incredibly challenging. I've seen many factories fail to get it right. It takes special skill. Let's dive deeper into the mechanics of injection molding, how the machines operate, and the costs involved. We'll explore everything you need to know.3

How are plastics formed with injection molding?

Struggling to visualize how a machine turns tiny pellets into a solid shape? It can seem like magic. But the entire process is a precise, repeatable engineering cycle.

Plastics are formed by melting raw material pellets and forcing them under high pressure4 into a closed mold. The molten plastic fills the mold's cavity, cools to a solid state, and takes the shape of the cavity before being ejected as a finished part.

The process of forming plastic parts is a fascinating cycle. It all starts with the raw plastic, which comes in the form of small pellets or granules. These pellets are fed into the injection molding machine through a hopper. From there, they enter a heated barrel where a large rotating screw pushes them forward. As the screw turns, it melts the plastic through both heat and friction.4 This turns the solid pellets into a hot, molten liquid.

Once enough molten plastic is ready, the screw acts like a plunger, injecting it at very high pressure4 into a custom-made mold.5 The mold is the negative of the final part you want to create. The plastic fills every tiny corner and detail of the mold cavity.6 After the cavity is full, the plastic begins to cool and solidify, helped by cooling channels5 within the mold.7 This is the most critical stage for delicate parts like plastic flowers, as this is where issues like shrinkage occur.8 Once the part is solid, the mold opens, and ejector pins push the finished plastic flower out. The whole cycle then repeats, allowing for the creation of thousands of identical parts. This method is incredibly efficient for mass production6.9

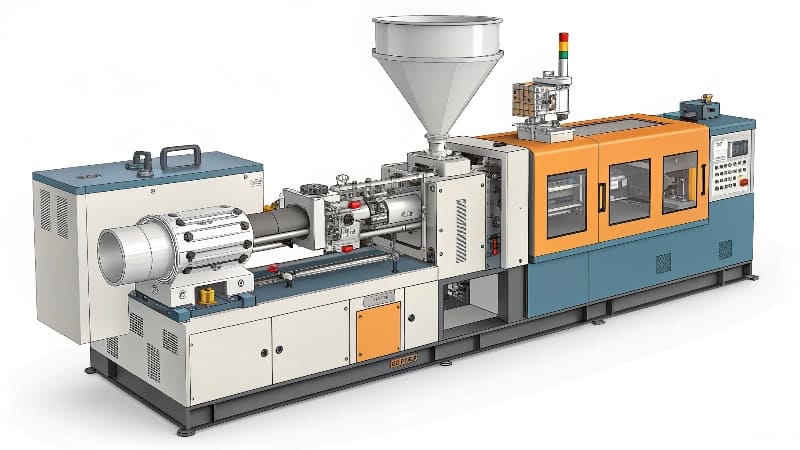

How do plastic injection molding machines work?

Confused by the different parts of an injection molding machine? Knowing the key components helps you understand the process. Each part has a specific job in making the final product.

An injection molding2 machine works using two main units: an injection unit and a clamping unit7. The injection unit melts and injects the plastic, while the clamping unit7 holds the mold shut during injection and cooling, then opens it to eject the part.

Let's break down how the machine operates, focusing on its two core systems. The entire process is a carefully timed sequence designed for speed and precision.

The Injection Unit

This is where the plastic's transformation happens. It consists of three main parts: the hopper, the barrel, and the reciprocating screw. Think of it as the "offense" of the machine.

- Hopper: This is the entry point. We pour the plastic pellets, sometimes mixed with colorants or other additives, into the hopper.

- Barrel and Screw: The pellets fall into the barrel, which is a heated cylinder. Inside, a screw rotates. This screw does two things: it pushes the pellets forward and its rotation creates friction, which helps melt them into a consistent liquid.

- Injection: Once enough plastic is melted at the front of the barrel, the screw stops rotating and moves forward like a piston, forcing the molten plastic into the mold.

The Clamping Unit

This part is the "defense." It needs to be incredibly strong to resist the high pressure4 from the injection unit.

- Mold Housing: The clamping unit7 holds the two halves of the heavy steel mold.10

- Clamping: Before injection, a powerful hydraulic or electric system pushes the two mold halves together with immense force, measured in tons.11 This ensures no molten plastic leaks out.

- Ejection: After the plastic has cooled and hardened, the clamping unit7 opens the mold. Ejector pins then push the finished plastic flower out, and the cycle starts again.

How much does a plastic injection molding2 machine cost in the US?

Wondering about the investment needed for injection molding? The cost varies greatly. It depends on the machine's size, features, and whether it is new or used.

A new plastic injection molding machine in the US can cost anywhere from $50,000 for a small, simple model to over $500,000 for a large, high-precision machine. Used machines offer a lower entry point, often starting around $20,000, but may require more maintenance.

The price of an injection molding2 machine is not a single number; it's a range influenced by several key factors. Understanding these factors will help you estimate the potential investment for your specific needs. The most significant factor is clamping force8, which is measured in tons. This force determines the size of the parts you can make.12 A small machine with 50 tons of clamping force8 is suitable for small, simple parts, while a large machine with 1,000 tons or more is needed for big items like car bumpers.

The machine's brand, origin, and technology also play a huge role. Machines from well-known German or Japanese brands are typically more expensive than those from China, but they often offer higher precision and durability. Additionally, you can choose between hydraulic, electric, and hybrid machines. Electric machines are more expensive upfront but are more energy-efficient and precise, making them great for complex parts. When calculating the total cost, remember to include auxiliary equipment9 like dryers, chillers, and material handlers, which can add a significant amount to the initial investment.13

| Machine Type | New Price Range (USD) | Used Price Range (USD) | Best For |

|---|---|---|---|

| Small (30-150 tons) | $50,000 - $150,000 | $20,000 - $60,000 | Small, high-precision parts, prototypes |

| Medium (150-500 tons) | $150,000 - $300,000 | $60,000 - $150,000 | Consumer goods, electronic housings |

| Large (500+ tons) | $300,000 - $500,000+ | $150,000 - $300,000+ | Automotive parts, large containers |

Is plastic injection molding2 profitable?

Thinking of investing in injection molding2? Profitability is a key question. Success depends on managing costs, optimizing production, and finding the right market for your products.

Yes, plastic injection molding2 can be highly profitable, especially for high-volume production10 where the cost per part becomes very low.14 Profitability hinges on efficient operations, mold quality, material costs, and securing consistent orders to maximize machine uptime.15

The profitability of this business really comes down to scale and efficiency. The initial investment in machines and especially molds is high. A single custom mold can cost anywhere from a few thousand to over a hundred thousand dollars.16 But once you have the mold, you can produce parts for just a few cents each. Therefore, the business model relies on high-volume orders to spread the initial mold cost over thousands or even millions of parts. The key to making money is keeping the machines running as much as possible. Every minute a machine sits idle, it's losing money.

Your choice of product is also critical. Making something complex like a plastic flower is a niche skill11.17 Only a few factories, mostly in the Zhejiang province of China, can do it well.[^18] This difficulty creates an opportunity. If you can master a difficult process that others can't, you can charge a premium. I once had a Canadian client who ordered a custom mold for 30,000 plastic flowers1. After we produced them, the specific material we used caused them to shrink slightly more than expected. I was worried, but when the client saw them, he loved the result even more because the shrinkage gave the flowers a more natural, delicate look. This happy accident shows that even challenges can lead to profitable outcomes if you have the right expertise.

Conclusion

Manufacturing plastic flowers1 via injection molding2 is a precise art. It requires mastering the machine's process, understanding costs, and turning challenges into unique, profitable opportunities for beautiful results.

- Explore the advantages of plastic flowers1, including durability and design flexibility, which can enhance your production process.

- Explore techniques that allow injection molding2 to achieve intricate designs and fine details.

- Learn about the injection molding2 process, a key technique for creating intricate plastic designs efficiently.

- Discover the critical steps involved in melting plastic pellets3, essential for understanding the injection molding2 process.

- Find out how custom molds12 can improve the quality and detail of your plastic products.

- Understand the role of high pressure4 in ensuring the molten plastic fills the mold accurately.

- Explore how cooling channels5 affect the quality and efficiency of the injection molding2 process.

- Learn about shrinkage issues13 in injection molding2 and how to mitigate them for better product quality.

- Understand how mass production6 can lead to cost savings and efficiency in plastic manufacturing.

- Get insights into the clamping unit7's role in maintaining mold integrity during the injection process.

- Compare hydraulic and electric systems14 to determine which is best for your manufacturing needs.

- Discover how clamping force8 influences the size and quality of the parts produced.

- Learn about essential auxiliary equipment9 that can enhance the efficiency of your injection molding operations.

- Explore how high-volume production10 can significantly reduce costs and increase profitability.

- Understand the key factors that determine the profitability of injection molding businesses.

- Find out how custom molds12 can lead to unique product offerings15 and higher profit margins.

- Discover how mastering a niche skill11 can set your business apart in the competitive plastic manufacturing market16.

- Learn about the manufacturing expertise in Zhejiang17 and how it impacts the quality of plastic products.

Explore the advantages of plastic flowers, including durability and design flexibility, which can enhance your production process. ↩

Explore techniques that allow injection molding to achieve intricate designs and fine details. ↩

Discover the critical steps involved in melting plastic pellets, essential for understanding the injection molding process. ↩

Understand the role of high pressure in ensuring the molten plastic fills the mold accurately. ↩

Explore how cooling channels affect the quality and efficiency of the injection molding process. ↩

Understand how mass production can lead to cost savings and efficiency in plastic manufacturing. ↩

Get insights into the clamping unit's role in maintaining mold integrity during the injection process. ↩

Discover how clamping force influences the size and quality of the parts produced. ↩

Learn about essential auxiliary equipment that can enhance the efficiency of your injection molding operations. ↩

Explore how high-volume production can significantly reduce costs and increase profitability. ↩

Discover how mastering a niche skill can set your business apart in the competitive plastic manufacturing market. ↩

Find out how custom molds can improve the quality and detail of your plastic products. ↩

Learn about shrinkage issues in injection molding and how to mitigate them for better product quality. ↩

Compare hydraulic and electric systems to determine which is best for your manufacturing needs. ↩

Find out how custom molds can lead to unique product offerings and higher profit margins. ↩

Explore current trends and insights in the plastic manufacturing market to stay competitive. ↩

Learn about the manufacturing expertise in Zhejiang and how it impacts the quality of plastic products. ↩